Cutting off the cable made from wire is a popular job carried out by various industries like productivity, telephone communication, and DIY works. Despite being accurate, mandatory precision, provision of access to the correct tools, and dedication to safety are required to make a smooth oblique cut. In this guide we will seek to examine the most current tools, safety precautions, and the best techniques for cutting wheel of cable, while including both statistic and graphical representations for better understanding.

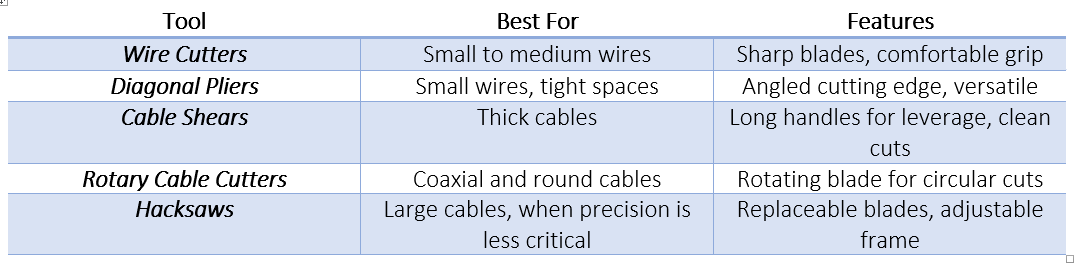

Tools for Cutting Wire Cable

The more suitable pair of scissors for the job requires to a clear knowledge of the type of cable you’re cutting and the degree of precision required within a particular job just like in aircraft cable. Here’s a comparison of popular cable-cutting tools:

Wire Cutters

These gadgets are wire cable cutters generally used at home and office. They are presented in various sizes and though they are perfect fit for small to medium cables, bigger wire sizes also have similar clamps. A wire cutter blade, in most cases, has sharp sharp edges and that makes a cut clean. Its grip is firmly and feels comfortable and safe in a hand.

Diagonal Pliers

Also called as diagonal pliers, these pliers are another versatile tool for snipping cables whether it’s the coaxial cable or the USB cable among other wires or even to create a cut in a tight fitting place. They cut inclined boundaries that cut out the interior wider part in a neat (precise) way.

Cable Shears

Cable shears have straight cuts and they are designed for cutting thicker larger cables. Unlike the cable cutters squashing and pulling the cable, the cable shears may leave clean cuts. The majority of them normally have ergonomic handle designs that can be easily handled for an extended time.

Rotary Cable Cutters

Such tools, labeled as cutter for round cables, smooth and end crossing, are made to trim coax cables. Such machine works in “scoring” fashion, the outer layer of copper is removed by the shoot of rotation. Rotor benders can be set to depth needed to vary cutting the sizes of cables.

Hacksaws

Although it lacks the precision of the other tools, a hacksaw can be utilized to cut a cable of a larger size in emergency situations when any other specialized tool is not available either in using bolt cutters hammer, angle grinder and bolt cutter. They are the multifaceted performers, the cutters of different materials, the myriad tools with replaceable blades.

As every tool is designed for a certain aim but may not be the best choice for all wire cables types. While choosing a cutting cable wire tool, you need to pay attention on the size and type of the cable and accuracy and cleanliness of the area around the cable.

Safety Measures

Here is an infographic illustrating the safety measures for cutting wire cable:

This must be taken into account and consideration as cable cutting safety is of key importance. Here are some essential safety measures:

- Wear Protective Gear: Eyes and hands safety glasses and gloves must always be used when work duties involve chance of injuries.

- Check the Cable: The cable must be free of any live voltage so it can prevent electric shocks by you through a voltage tester.

- Secure the Cable: Grab or Measurably the cable lest it slips out.

- Cut at a Right Angle: This will help to prevent fraying. It is therefore advisable to try leaning the knife at a right angle when cutting threads.

- Dispose of Waste Properly: For a proper disposal, cut off the ends of old wires.

What is the process for cutting steel cable or cut wire rope?

Here’s a concise guide to cutting steel cable:

- Choose the right tool. Cable cutters, angle grinders and hydraulic cutters, as an example, are the tool types to be used for a given diameter of the steel cable.

- Measure and Mark: Use the measuring tape to assess the expected required length and find the transgression point on the wire.

- Secure the Cable: Attach the cable firmly to prevent any possible cord oscillations or vibrations during the cutting process.

- Fray Prevention (Optional): Wrap the cutout with tape or cover with a cable frayed ends cap to inhibit fraying.

- Cut the cable: Choose the device from the work station and cut the cable at the noted point. Bearing a pressure cuts clean.

- Clean the Cut: Remove the negative impact or nasty aesthetic of any brittle strands by using a file or grinder.

- Safety Precautions: Use brands or safety glasses and follow instructions from the manufacturer of the tools and their usage.

- Maintenance: Maintain the adequacy of cutting tools by ensuring; they are always sharp.

What are the different types of wire rope cutters?

Here is an image showing the different types of method wire rope cutters, each labeled with their names:

Manual Cable Cutters

Hand powered tools is the better choice for cutting cables that are small and medium in size. Generally they come with two handles and a blade to be used for the line cutting, requiring an operator to forcefully pull the rope through to sever the wire.

Hydraulic Cable Cutters

These kind of knives get leverage from the hydraulic pressure which makes them to cut through bigger and harder cables. They are usually utilized in demanding situations such as in the call service industry and can use hand power or hydraulic pressure.

Pneumatic Cable Cutters

The air-reacting cutters that are required for cutting metal mostly in a thin and even way in workshops. Those are typical of the applications where pistons and cylinders do not work appropriately with either hydraulic or electric power.

Ratcheting Cable Cutters

This cutting tool is equipped with jaws and an interior ratcheting unit that enables you to cut tough cables with less strength. They are responsible for cross-cutting the larger diameter cables with a minimum strain from the operator’s hand.

Electric Cable Cutters

A battery-operating machine or an electrically powered cutter which give a easy-to-handle and quick cutting solutions. They are well suited to repetitive cutting as well as it suits them to be used in the construction of electricity and telecommunications and so on.

Why do you need a quality cable cutter?

Cables, however good you may be at cutting with scissors, only a premium wire cutter can make clean, precise cuts. Additionally, it makes your work easier, and saves you time, as well costs as well as ensuring the safety of your equipment.

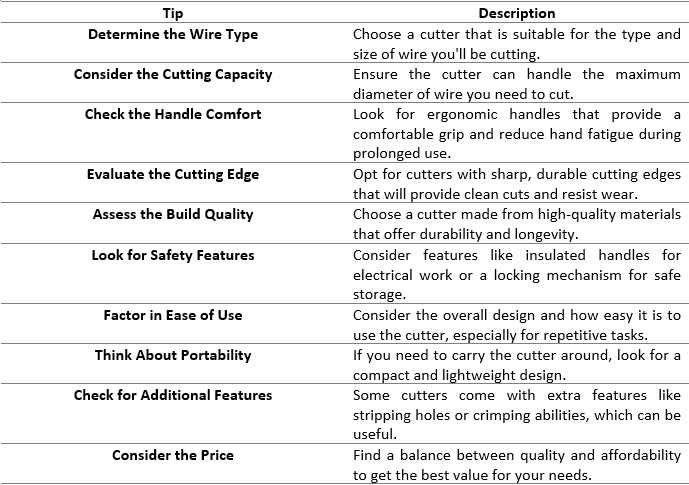

What are the tips in choosing a wire cutter?

Here’s a table with tips for choosing a wire cutter:

During your choice, analysis of uses and suitable features of the wire cutter for your particular project should be made in the first place and later you hope you will be provided with a tool that satisfies them and creating and provides comfort, safety and durability.

Choosing what Wires you want to cut?

When choosing what wires you want to cut, consider the following factors:

- Type of Wire: A the same time the cutters that work with solid ,stranded or braided wires are not the same type too.

- Wire Size: This information is a very important factor determining the required diameter of the cutter.

- Material: It is this fact that influence the form of cutter wire, as the copper’s and aluminum’s hardened steel are different from each other.

- Insulation: When this wire is insulated, consider that cutter may or may not strip the insulation without damaging the wire.

- Application: The wires’ intended use, which could be either for electrical, communications, or industrial use, is among the factors that influence the type of cutter.

- Frequency of Use: You should choose an endurance cutter of maximum quality in the case of a heavy duty use involving with wires cutting.

Best Practices

This is one of the reasons why it is always useful to study cases where haircuts were successful as well as those where they were challenging.

- Choose the Right Tool: Select an ideal cutting tool suitable for the character and diameter of the cable. Employing the right tool is vital in getting a good pair result or not punching the tool itself.

- Keep Your Tools Sharp: Sharpening is essential so keep your cutting tool sharp on regular basis to avoid its bluntness. Beveled-down blades may tear or cut up the cord cable.

- Measure Twice, Cut Once: It is extremely important to measure your materials twice before cutting. Instead of making the cable shorter that much hastily, it is more proper to spare some time and ensure the exact length without mistake.

- Practice Good Technique: Keep the stroke you make consistent and don’t be too vigorous with pressure. The best approach you will take is the one which you cut without twisting or bending the cable since this can break the internal connection.

- Follow Manufacturer Guidelines: Follow the cable’s cutting instructions verbatim if it gives any details about how to cut cable end it. Such practice can be employed in order to protect the cable’s internal structure from damage.

The behavior to cut steel wire rope?

Stainless steel is well-known for its corrosion resistance, strength and durability without the hassle or need for frequent or costly repair. The base bone, as well as tooth enamel which keeps its appearance over time, can endure high temperatures and hostile conditions. In addition to that, stainless steel is non-magnetic and offers wide ranges of hard surface finishes, thus wide usage of this type of steel rope for various purposes.

Cutting Stainless Steel Cable with Hand Cutters

To cut stainless steel cable with hand tool cutters:

- Choose the Right Cutters: Stainless steel is not easy to cut. Hence, use strong cable cutters which are meant for cutting stainless steel.

- Measure and Mark: Measure the appropriate length and mark out where you will cut.

- Secure the Cable: Connect the cable to aviod during the cutting process.

- Cut the Cable: Crop and align cutters, if necessary, and then exert pressure in a proper way to make an accurate cutline or clean cut.

- Inspect the Cut: Inspect for torn parts and tidy them up with a file if this is unavoidable.

Make sure that you put on the safety gloves and goggles while handling chemicals.

Conclusion

The functioning of cutting the wire cable is something you must be cautious with, follow the necessary safety measures, and employ the proper equipment to do it efficiently and optimally. By adhering to the same amount of rules and tips, you’ll get a clean, safe cut every time and cutting small cable with a sharp cold chisel. Irrespective of your professional status or whether you are a DIY enthusiast, the ability to cut wire cables correctly is a useful skill that should be mastered to ensure the correctness of any cable projects and it cost effective t not too expensive some of the materials .